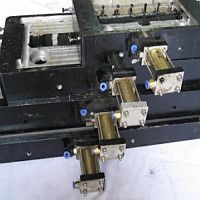

Automatic Battery Assembling Plant

Air Leakage Testing Machine, Automatic Heat Sealing Machine, Fixture, Hole Punching Machine, Inter Partition Welding Machine, Punching Machine, Short Circuit Testing Machine and Stress Testing Machine they all are present under the range of Automatic Battery Assembling Plant, which we offer. These Automatic Battery Assembling Plants are manufactured in accordance with the established industrial norms. Requirements

- Lead

- Battery Plates

- Battery Separators

- Battery Casings and few others small items as a raw material

- The Process starts with Casting of Lead parts like Poles, Lead Connections 'L' with the help of Small Components Casting Dies along with Plate Grouping Dies for jointing all plates to form a cell. Now, the process moves ahead with a Battery Assembling Plant

- The selection of a battery assembling line starts with the number of batteries requires manufacturing, indulging number of labors in process & types of models/ segment of batteries to manufacture. With This, Such Plates Cells are placed in a Battery after Punching the Battery Container with the help of Container Hole Punching Machine

- Each battery has its own different size, for every size we require an individual Hole Punching Die that is fitted on the machine & can be changed as per the desired model of battery to manufacture. After this, the plates cells are placed in the container, Then such cells are inter connected with other cells through Inter partition welding through help of Interpretation Welding Machine

- In our machine, the settings of individual type of battery can be done selected by its model name whether it is of 50Ah, Din Series, or N200 model. Even laymen can work with that. Then, the welded joint is checked with the Short Circuit Testing Machine

- If the plates are short, major hole in separator is there & any cell out of five welds is not joined then it will be indicated by individual cell indicator & by buzzer alarm with Stress Testing Machine

- Put a certain pressure on the welded joint to check the quality of the welded joint with Air Leakage Testing Machine

- Passing a certain air pressure on the sealed battery for checking its sealing to avoid chances of leakage of sealed battery casing from its entire corner

To enquire about the desired product(s), just check the box and then click �Inquiry Now� button which is provided below.

|

Durability : Long Life Surface Finishing : Polished Resistivity : Rust Resistant Material : Metal Application : Industrial Drive Type : Electric |

Select  and click Enquiry Now

and click Enquiry Now

Contact Us

Mobile : +91-9873334982, +91-7057769666

Call Us : View Primary Number