| Business Type | Manufacturer, Exporter, Supplier, Retailer |

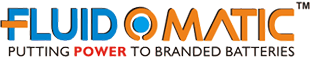

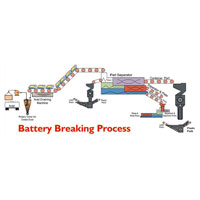

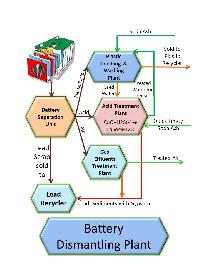

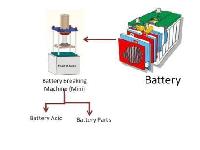

We are counted among one of the leading Manufacturers and Exporters of a wide range of Battery Breaking Plants. Designed and fabricated using the latest CAD/ CAM technologies and premium raw materials, our entire range of Battery Breaking Plant is reliable and highly efficient. Our team of experienced engineers enables us to construct high performance Battery Breaking Plants that are easy to assemble, commission, operate and manage. The range of Battery Dismantling & Separation Units we have are designed for different capacity, investment and labor deployment.

They are mentioned as follows :

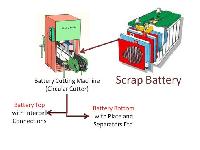

- Battery Crusher ( Mini) useful for small units

- Battery Cutting Machine useful for small units

- Battery Slicer ( Available in three configuration) useful for Medium Scale units

- Battery Crusher useful for Bigger units

The system is controlled through Control panels [PLC operated unit integrated]. The plant has individual operational control system on feed conveyors also for operators. A master control panel is attached in the Main Control Room as provided by the customer nearby the plant. The Plant has additional feature of Auto Shut Down with the Self Fault Facing Indication displays. These displays can be fixed up as per the custome defined position within Five meter range. This helps in knowing the actual position of the plant & reduces the lead time period to search for the errors & with faster production.

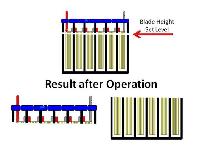

Construction & Structure

The Breaking system is built exclusively of SS steel grade 306,310(as pe availability), & the Acid Proof Plastic Coating is done on certain parts which indirectly come into the contact of Acid; Stainless steel assures trouble free operation and increased durability. These classification units, are designed as complete system, it provide low initial cost with high efficiency. The system also offers low maintenance, easy installation and start up, low power consumption and water consumption is only for Floatation process in separating Lead & Lid Parts, this water is filtrated and reused with the same up to its fullest and later on, it can be re used in making balls of Oxide dust for feeding in Oxide mills.

Features

- Systems are useful for small or large capacity operations.

- SS Steel is used in plant & Special Acid Proof Plastic Coating at some parts is done to keep the cost to minimum & for plant�s durability.

- High level of automation with the PLC units is there for auto Controlling & Self Fault Indication display.

- Auto Shut down of Plant for facing any errors increase plants life & ensures safety.

- Low Power Consumption.

- Machines are completely enclosed for making it environment friendly & reducing Material Wastages.

- Machine is Rugged & Heavy Duty. It is capable of running for 18-21 Hrs. continuously.

Benefits

- Low labor costs.

- 99%+ Lead yield.

- Low energy costs.

- Environment Friendly.

- Low maintenance costs.

- Saves Warehousing Costs.

- Reduced processing cost per ton.

- Simplified environmental compliance.

- Reduces the market DEMAND-SUPPLY Gap.

- Helps in maintaining & keeping costs of Raw Material

Raise your Query

Hi! Simply click below and type your query.

Our experts will reply you very soon.