| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Specifications | |

| Brand Name | FLUIDOMATIC |

| Driven Type | Mechanical |

| Click to view more | |

Product Details

For those wishing to purchase reliable and high performance Battery Separation Systems, we are the best place. Our company is one of the reputed Manufacturers, Exporters and Suppliers of a comprehensive assortment of Battery Separation Systems inclusive of Battery Splitter and Battery Slicer/Cutting Machine. Well-known for their optimum functionality and high capacity, our Battery Separation Systems are the best. We provide them in bulk and provide exemplary after sales support for it.

We have four types of Battery Breaking Systems/ Crushers depending upon output and investment.

- Battery Splitter; for Small Output Requirement i.e. 500 kg to 1000 kg /Hour

- Battery Slicer; for medium Output Requirement i.e. 3 Ton/Hour

- Battery Parts segregation and De-Sulphation Plant

- Battery Crusher; for large Output Requirement

- Battery Slicing Machine

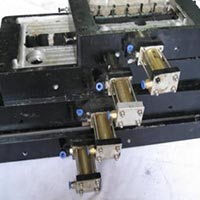

Battery Splitter : This splits battery into two pieces - lid and bottom of battery. Then Battery can be splitted into many sections as required. This machine can be used for Motorcycles, UPS, Automotive, 2 volt Cells, PP as well as for Hard containers PP or Rubber container batteries. The Machine has working stations for Pole Extraction and Connection Breaking. Acid will drained out to the bottom tank. The tank is made with high quality Stainless Steel. Extracted Pole and connections are collected in the bins. The whole splitting process is driven by mere 5 KW motor. Output is 20 ton/day.

Description : This Machine is hydraulically powered and has one Battery Lid splitter station One for Pole extraction, and remaining for crushing small sizes of battery i.e. motor cycles, UPS, etc.

Process of Operation:

Battery is placed on guillotine horizontally and operate a lever so hydraulic Ram moves downwards and Battery is splitted from its sealing position

Operation of Machine :

Batteries is placed inside a Stainless Steel Cage. Operator will initiate the cycle of machine by pressing an operator Handle/ Foot operated Switch. Battery is Splitted by Hydraulic Ram. Battery Acid and Battery Parts are collected in bottom Tank. Acid can be pumped to Acid Neutralizing Unit, where acid neutralized by that unit.

Output of Machine is Pieces of battery parts ( mix of all parts including Plastic parts). Acid drained out in to Acid tank.

Size of Machine : 800 mm X 1700 mm X 1800 mm Approx.

Battery Slicer/Cutting Machine :

- We have THREE models for this category as under :

- Single stage Slicer : This machine slices off battery into pieces horizontally (two, three or four pieces) depends upon models. Electricity load requirement of the machine is 5.5 kW. Labor required - two to place battery on conveyor only rest work is done by machine. Output of machine 40 ton/Day.

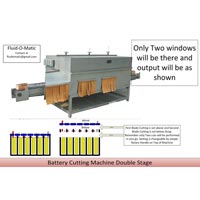

- Double Stage Slicer : This machine slices off the battery to the two different heights. Required Electricity load is 10.5 kW. Labor required is two to place battery on conveyor. Output of machine 40 ton/Day.

- Triple Stage Slicer : This machine slices off the battery at three different heights into four pieces. Required Electricity load is 15.5 kW. Labor required two to place battery on conveyor. Output of machine 40 ton/Day.

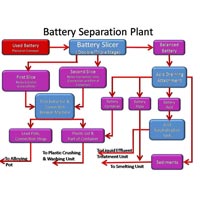

Flowcharts 01

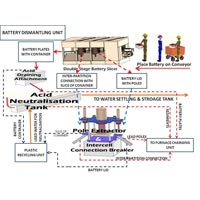

Flowcharts 02

Looking for "Battery Breaker Parts Separation Plant" ?

Explore More Products