| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Specifications |

Lead to be manufactured from Rotary Furnace can be obtained directly from scrapped batteries or as slag from Mini Blast Furnaces In case of former batteries are cut open or broken to segregate lead scrap, plastic and other materials from them; lead scrap in the form of lead powder/ plates etc. is charged in the furnace along with a proportionate charge of additives. In The case of latter, slag produced from Mini Blast Furnaces is charged into the Rotary Furnace, again with proportionate additives.

This process is a batch type process. After filling the required quantity of raw material (either manually or mechanically), the lid of the furnace at the front is closed. The burner attached to the moving door is then fired.

The Rotary Melting Furnace is very flexible and universal equipment used for recycling many non-ferrous metals. It is the major lead production technology used in India and many other countries for Secondary Lead Production. A lead production system based on this technology has certain distinct characteristics such as :

- Equipment scalable for installing higher capacities

- Recovers all lead in one production cycle

- Plates & powder from scrap battery as well as slag from Mini Blast Furnace can be used as raw material

- Requires addition of certain consumables

- Can be fired with various fuels

- Generates high Pollution both as Flue Gases & Fugitive Emissions

Apart from plates and paste of lead oxide from scrap batteries, slag from Mini Blast Furnace is charged in the Rotary Furnace.

In addition to these, certain compounds of sulphur are also present in the batteries. When this material is heated in the Presence of carbon, lead oxide is converted to lead. This conversion along with burning of fuel generates flue gases and fumes containing dust, dirt, oxides of lead, lead particles and such other impurities etc.

Hence, to meet various goals of maintaining employees' health and factory environments as well as regulatory requirements, it becomes imperative to get high end Air Pollution Control Systems to be installed with the Rotary Furnaces.

Rotary Chamber Advantages :

- Recovers 100% lead in the first operation.

- Slag produced is lead free.

- Equipment can be scaled up for higher production capacities.

- Many chemicals are required for operation.

- High power consumption.

Rotary Furnace :

We have two models of Rotary Furnace, one without barrel (Flame Shape) and another with barrel (furnace body). Both designs are advantageous, depending upon requirements.

Barrel Type Rotary Furnace :

This is traditional design. Smelters have been using this type of furnace from very olden days around the world. But the final product is MIXED Lead (DOGALA Lead) and the recovery is also lesser as compared to our newly designed Rotary furnace. I will explain it in next paragraph. The reason for lesser recovery is cogging of slag into the tap out hole and In this turning process molten lead is mixed with slag and small amount of lead is retraped with slag so recovery is further reduced. So we designed Rotary furnace without barrel.

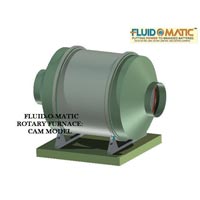

Rotary Furnace without Barrel or Flame Shape Rotary Furnace :

In this type of furnace, following advantages had been practically gained :

Barrel type Rotary was designed for Iron Smelting, not for Lead, as we all know, thermal conductivity of Iron is very much different than Lead. Iron thermal conductivity is 80 while Lead thermal conductivity is 35 W/(m K). It considerably reduces with temperature. So, we increased L/D ratio of Furnace. This reduces temp. of exit gases, hence utilisation of energy is increased.

Raise your Query

Hi! Simply click below and type your query.

Our experts will reply you very soon.