Sector 60, Noida, Uttar Pradesh

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

We offer the Temple Furnace at the market leading. This Temple Furnace is known for its quality and long, hassle-free performance. A Mini Blast Furnace (commonly known as MandirBhatti or ShahiBhatti) is a simple, time-tested and widely used system to produce secondary lead in India and many other countries. It is the most basic of all furnaces and a production system based on this technology.

About Mini Blast Furnace

The Temple Furnace itself is a modified blast furnace which consists of a brick lined structure with fire brick oven in the midst and a metal Exo-skeletal structure outside. Raw material & fuel (coke) is charged manually through the side metal doors fitted in the brick structure and air is provided from the FD fans provided at the back of the brick structure. Molten metal & slag is tapped at the pits made in front of the brick structure and flue gases are sucked from the top of the brick structure which is provided with a metallic hood.

Lead to be manufactured from Mini Blast Furnace is usually obtained from scrapped batteries. They are cut open or broken to segregate lead scrap, plastic and other materials from it. Lead scrap in the form of lead powder and plates etc. is charged in the furnace along with a proportionate charge of wooden coke. Thereafter the furnace is manually fired with the help of rags. FD Fan provides the necessary air required for combustion from the back of the furnace. Coke in the oven performs the functions of both, the fuel as well as a reducing agent for obtaining lead from its oxides charged in the form of lead plates & Powder. Temperature of the furnace is maintained at the desired level for approximately 30 minutes, after which molten lead along with slag flows out from the bottom of the oven into the outlet pit. Here slag is separated and molten lead is poured into Ingot Molds. To maintain this, continuous charge of raw material and coke is maintained in the furnace. This process leads to generation of flue gases which are toxic in nature and need appropriate and adequate Air Pollution Control System for their treatment.

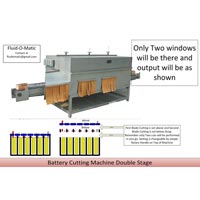

Temple furnace Is Of Two Types:

- Single Temple Furnace

- Double Temple Furnace

Characteristics

- Low Project Capital Cost

- Low Energy Cost (wooden coke fired)

- Easy to install

- Easy to operate & maintain

- Production of low Antimony Lead (soft lead) at low temperature

- Generates high pollution

Looking for "Temple Furnace" ?

Explore More Products